ALEXANDRIA: Development of new generation techniques and methodologies for damage inspection and dimensional metrology for the aeronautics, railway, naval and wind power sectors

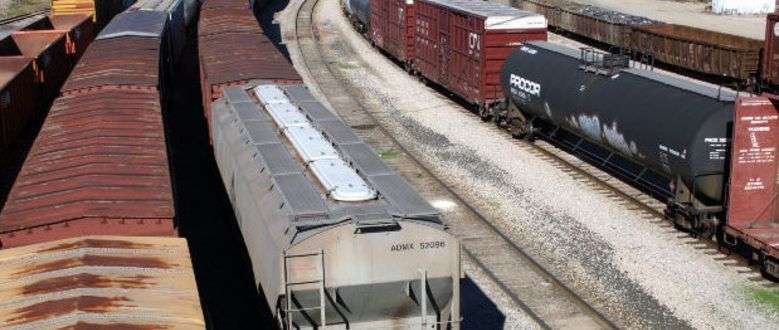

Inspection and Defect control of large-dimensioned component manufacturing and service operation in high value sectors such as aeronautics, railway, naval and wind power, share a common problem: both of them have to be highly reliable, which means it requires the appropriate technology for the examination and control of manufacturing defects.

The inspection technology currently available is limited to manual inspection methods, which requires long inspection periods of large-dimensioned parts, in order to guarantee reliability, and so restricting actors' productivity and competitiveness in the value chain.

Facing difficulties, this project tries to develop new and non-destructive inspection techniques and methodologies without damaging contact, in order to lay the foundation for a medium-term development of automated, accurate and reliable inspection solutions aenaeronautics, railway, naval and wind power sectors, aiming to increase their competitiveness by improving their productivity, efficiency and reliability.

Objectives

- To focus on the scientific and technical work required to develop new techniques and methodologies for non-contact 3D digitizing, based on advanced optical techniques such as high-accuracy photogrammetry, introducing this way a precision leap -not only qualitative, but also quantitative- in this kind of techniques.

- To study the viability of an inspection equipment for railway bearings and train brakes, entering and leaving railroad workshop.

Project

/research/projects/desenvolvemento-de-tecnicas-e-metodoloxias-de-inspeccion--de-danos-e-metroloxia-dimensional-de-nova-xeracion-para-os-sectores-aeronautico-ferroviario-naval-e-eolico

<p>Inspection and Defect control of large-dimensioned component manufacturing and service operation in high value sectors such as aeronautics, railway, naval and wind power, share a common problem: both of them have to be highly reliable, which means it requires the appropriate technology for the examination and control of manufacturing defects.</p> <p>The inspection technology currently available is limited to manual inspection methods, which requires long inspection periods of large-dimensioned parts, in order to guarantee reliability, and so restricting actors' productivity and competitiveness in the value chain.</p> <p>Facing difficulties, this project tries to develop new and non-destructive inspection techniques and methodologies without damaging contact, in order to lay the foundation for a medium-term development of automated, accurate and reliable inspection solutions aenaeronautics, railway, naval and wind power sectors, aiming to increase their competitiveness by improving their productivity, efficiency and reliability.</p><ul><li>To focus on the scientific and technical work required to develop new techniques and methodologies for non-contact 3D digitizing, based on advanced optical techniques such as high-accuracy photogrammetry, introducing this way a precision leap -not only qualitative, but also quantitative- in this kind of techniques.</li> <li>To study the viability of an inspection equipment for railway bearings and train brakes, entering and leaving railroad workshop.</li></ul> - Xosé Manuel Pardo López - Xosé Ramón Fernández Vidal, Víctor Leborán Álvarez

projects_en